How to deal with engine misfire failure?

Table of Contents

ToggleIn the maintenance of engine failure, especially the engine idle shaking or exhaust emissions exceeding the standard fault, maintenance personnel often encounter faulty diagnostic instruments prompted by the engine being out of the fire, which we should have a correct understanding of. Engine misfire, high concentrations of hydrocarbons will enter the exhaust system, resulting in excessive exhaust emissions. The high concentration of hydrocarbons will also increase the temperature of the three-way catalytic converter, which may cause damage to the three-way catalytic converter in severe cases. The following is an example of a Toyota model that can be used to analyze an engine misfire.

Monitoring of engine misfires

To prevent excessive exhaust emissions and thermal damage to the three-way catalytic converter, the engine control unit uses the crankshaft position sensor to monitor deviations in the rate as the engine is turning to determine misfires, and the camshaft position sensor to identify cylinders that are misfiring. The engine control unit starts counting the number of engine misfires when the engine misfire rate exceeds the threshold value, which may result in exceeding the emission limits.

Classification of engine misfires

Engine misfires can be simply categorized into two situations, one is a complete misfire which means there is no combustion, and the other is a partial misfire which means the combustion is unstable. OBD II defines three levels of engine misfires, A, B, and C. The OBD II is the first of its kind in the United States.

- Type A misfires are the most severe type of misfires and are close to damaging the three-way catalytic converter. If detected, the engine malfunction warning light flashes to alert the driver to repair it immediately and to store fault codes and data frames according to the first trip logic. The engine diagnostic system identifies Type A misfires by counting the number of misfires in 200 engine cranking revolutions.

- When a Type B deflagration occurs, emissions of hazardous substances in exhaust gases increase by more than 1.5 times.

- Type C deflagration is the least severe type of deflagration and can lead to substandard vehicle emissions.

The engine diagnostic system identifies Type B and C misfires by counting the number of misfires in 1,000 engine crankshaft revolutions; Type B and C misfires occurring consecutively on two trips will cause the engine control unit to store a fault code and illuminate the engine fault light. An engine with the correct air-fuel ratio, adequate ignition, and good mechanical condition will not suffer from a misfire; if there is a problem in any of these areas, combustion will end prematurely, resulting in a misfire.

Engine misfire overhaul

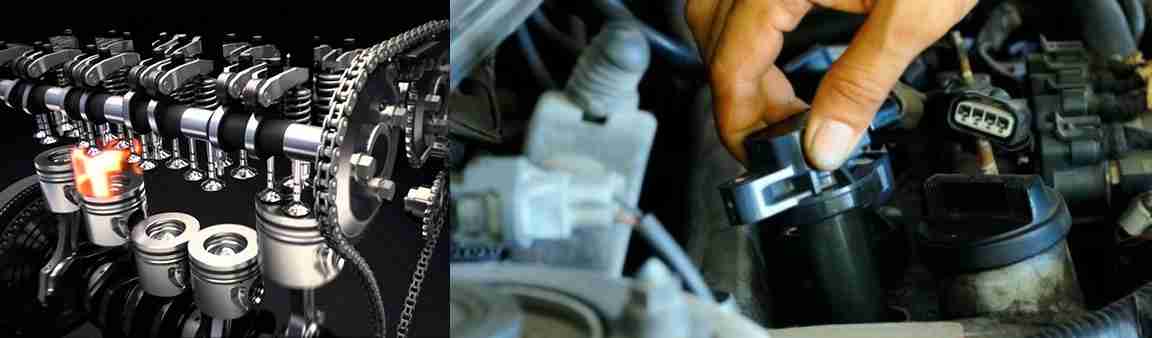

In the process of troubleshooting engine misfires, you need to pay special attention to 3 points: cylinder pressure, ignition, and fuel injection.

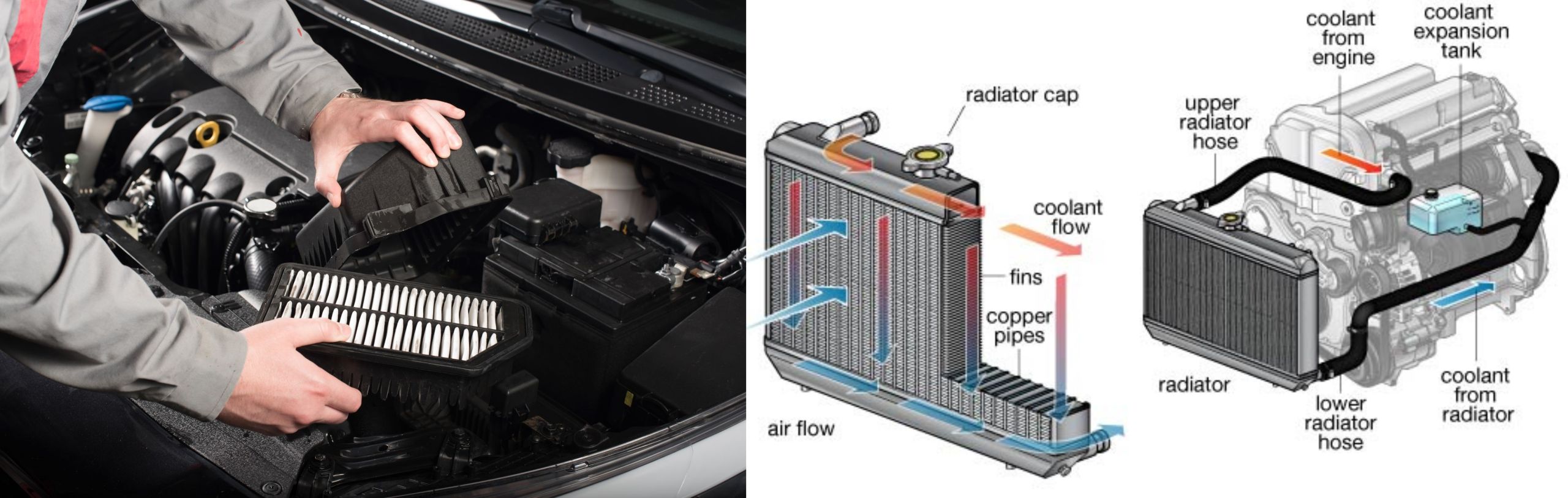

- Cylinder Pressure: This can be easily detected using a cylinder pressure gauge and will not be repeated here, but take into account that changes in the hardness of the valve springs and the degree of wear on the camshafts are difficult to detect when measuring the cylinder pressure, as well as whether or not the intake volume is sufficient (air leakage or valve carbon buildup).

- Ignition: For the engine’s lack of fire repair, sometimes only by reading the engine data flow is not able to find the problem, but also with the help of oscilloscopes to make further judgments. Ignition to consider factors including ignition timing, whether spark plugs work properly, whether the resistance of the high-voltage wire is in the standard value range, whether the ignition coil works properly (power line and signal line whether the false connection), and the engine control unit work properly (including CAN data to provide the signal).

It is recommended to use instruments to test as much as possible, for example, you can use an oscilloscope to check the synchronization between the camshaft sensor and the crankshaft position sensor, and be able to analyze the existence of misfire and the accuracy of the ignition timing and the gas distribution phase; use an oscilloscope to check the working condition of the ignition coil and the ignition time, and at the same time, be able to analyze the spark plugs; use an oscilloscope to check the connection of the data wires between the control units; use a megohmmeter to test the resistance of the spark plugs; use a multimeter to test the resistance of the high voltage wires. resistance of the spark plug; check the resistance value of the high-voltage wire with a multimeter.

- Fuel injection: First, through the data stream to see the injection pulse width, ignition time, and the working condition of the oxygen sensor, second, using an oscilloscope to check the throttle position sensor TPS and injector synchronization, check the synchronization of the TPS and oxygen sensor, then check the synchronization of the injector and the oxygen sensor (spraying detergent into the air intake at idle to check the changes in the injector and oxygen sensor), and finally, to check the injector’s waveforms, analyze the injector’s goodness and the length of the injection time (compare with the standard waveforms), and finally, consider the gasoline grade used, the burst sensor, and the three-way catalytic converter.

Many repair stations like to use the replacement method to check for misfire faults, although I do not recommend this, sometimes this can be a quick way to troubleshoot. If the swap method is used for checking, the following swap method is recommended.

For example, if a 1-cylinder misfires, we can swap the 2-cylinder wiring with the 1-cylinder, the 3-cylinder injectors with it, and the spark plugs can be interchanged with the 4-cylinder so that after swapping the cars we test them until the failure occurs again. If the fault becomes a 2-cylinder misfire, it is the problem of the cylinder line, if it is a 3-cylinder misfire is the problem of the injector, and so on. If the fault doesn’t shift, consider mechanical failure or other component failure.

The engine’s lack of fire troubleshooting is not complicated, usually more ignition system failures, sometimes the failure point will also appear in the mechanical or engine electronic control. Below, the author combined 2 specific fault cases to briefly explain the lack of fire fault repair.

A case of engine misfire failure

Case 1

Inspection and analysis: after parking the car overnight, the next morning the engine idle was shaking. Using the Toyota Intelligent Tester, no engine fault code is stored; check the engine data flow, and found that the 2-cylinder misfire. After interchanging the 2-cylinder and 3-cylinder ignition coils, the 2-cylinder misfire prompt disappeared, and the 3-cylinder misfire appeared.

Troubleshooting: the analysis is that the 2-cylinder ignition coil works poorly in the cold state, after replacing the 2-cylinder ignition coil, the phenomenon of the engine idling jitter disappears.

Case 2

Malfunction: A 2006 Toyota Corolla sedan equipped with a 1ZZ-FE engine. Users report that the engine fault light is on and the engine shakes at idle.

Inspection and analysis: the use of the Toyota Intelligent Tester test, call the engine fault code for P0304 (detected engine cylinder 4 misfire), view the engine misfire data frame: engine speed 724r/min, the total number of ignition 391 times, the engine 4-cylinder misfire number of 4 times.

A basic check of the engine was performed, but no problems were found. Replaced the ignition coil, spark plugs, and injectors, but the engine still does not fire. Suspected that there is a problem with the engine intake and exhaust system, measuring cylinder pressure, measured 1 cylinder, 2 cylinders and 3 cylinders pressure are close to 1.4MPa, 4 cylinders pressure is 1.2MPa, although smaller than the other 3 cylinders’ pressure of 0.2MPa, but also in its normal range of difference.

It was finally decided to further check the engine intake and exhaust system with an exhaust gas analyzer. To meet the strict requirements of the emission regulations, so that HC, CO NOx, and other harmful gases such as zero emissions, modern engine control systems must always control the actual air-fuel ratio in the theoretical air-fuel ratio of 14.7: 1 (that is, the excess air coefficient is always 1) near. The measured composition of the exhaust gas when the engine is idling is: CO2 is 9.94%, O2 is 8.09%, HC is 596×10-6, CO is 0.784%, NOx is 0×10-6, and the excess air factor is 1.5.

When the engine speed is stabilized at 3000r/min, the excess air coefficient is close to 1, which indicates that the control system of the engine control system at high speed is normal for the control of the actual air-fuel ratio. I suspect that when the engine is working, there is no airflow meter air into the cylinder, resulting in the idle mixture being too thin so that the excess air coefficient is greater than 1. Remove the valve cover, and check the valve timing is normal. Check the intake and exhaust valve clearance, and found that 4 cylinder 2 exhaust valve, there is no clearance, always on top of the camshaft, resulting in the valve not being closed, there has been air leakage. Dismantle the engine cylinder head and find that the valve seat of the exhaust valve that always leaks is sinking.

Troubleshooting: 4 cylinders of the engine sinking exhaust valve seat repair, and replace the 4 cylinders of the 2 into 2 rows of 4 valves and cylinder head of all 16 valve oil seals, mounted after the troubleshooting.

Yeahengine, an automotive engine supplier, offers a comprehensive range of products. You’ll find factory original wholesale engine assy, hot sale complete car engines, used automobile engine assemblies, factory original car engines, long block engines, special sale engine blocks, and racially hot selling professional OEM ODM service auto engines. We also provide wholesale bare engines. With our extensive selection and numerous advantages, we are your one-stop destination for all your automotive engine requirements.